Home > About AIBT

In 1999, Advanced Ion Beam Technology, Inc. (AIBT) was founded in Silicon Valley before establishing the Headquarters of Operation as well as the R&D and Manufacturing Center in both the Hsinchu and Tainan Science Parks in 2003.

The ions implanted by the ultra low energy ion implantation machine developed by AIBT have driven the high-performance operation of the world’s advanced logic and communications chips. By building a solid foundation through 28nm processes and long-term partnerships with the world’s leading semiconductor manufacturers, AIBT has been accumulating core technologies and manufacturing processes over twenty years and is propelling to advanced next-gen nano processes using said technologies and processes. Meanwhile, AIBT has also made the most critical technologies of equipment fabrication deep-rooted in Taiwan.

From the earlier iPulsar to iPulsar Plus to iBlazar, AIBT has evolved along the way and fabricate up to 50 machines annually. Up to 80% of AIBT’s equipment comprises domestic parts, driving the development of the domestic parts supply chain and reducing development costs, while providing exceptional customization services that are localized and flexible. In the future, AIBT will continue to recruit the top development talent in ion implantation technology and experts in semiconductor manufacturing processes as we continue to strive toward the research and manufacturing of equipment for core semiconductor processes.

Founding date: August, 2003

Founder: Archie Hwang

Chairman: David Chen

President: Chris Chern

Number of Employees: 200

The research, development, manufacturing, and sale of ion implantation equipment and system parts

By recruiting top development talent in ion implantation technology, AIBT is committed to the research and manufacturing of equipment for core semiconductor processes. Our long-term partnerships with the top semiconductor manufacturers offer clients the best productivity performance as we continue challenging the development requirements of cutting-edge manufacturing technologies.

Our R&D engineering, software development, and production manufacturing teams have established an advanced manufacturing base in Taiwan as well as a resilient supply chain. AIBT’s accelerated integration of upstream and downstream industry resources has achieved reduced costs as well as fast and flexible services that meet the demands of clients.

Up to 80% of the equipment comprises domestic parts in areas such as vacuum, wafer transfer, microcontrollers, electromagnets, high-voltage insulation, power supply, and graphite components, boosting the development of domestic industries.

Client-oriented Approach: AIBT’s client-oriented approach focuses on gaining an in-depth understanding to satisfy clients’ demands.

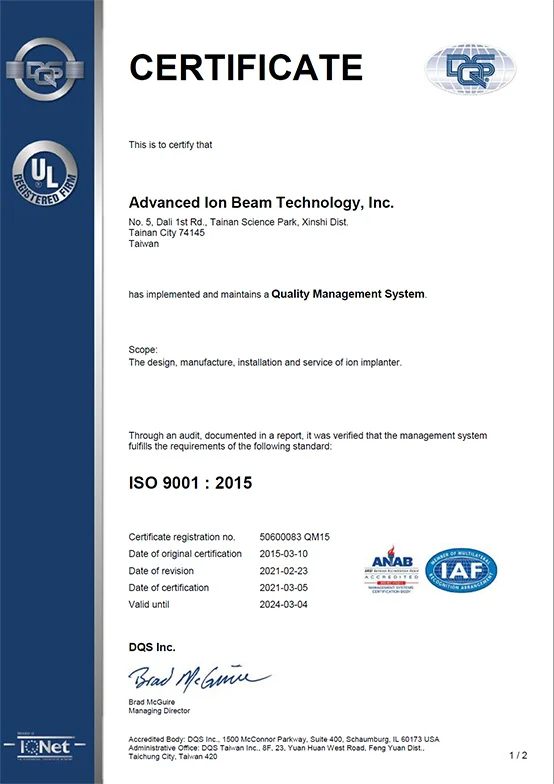

Exceptional Quality: Pursuit of high-quality production and services at reasonable costs.

Continuous Improvement: Implementation of company-wide quality management

7F., No.18, Puding Rd., East Dist., Hsinchu City 300047, Taiwan

Tel:+886-3-577-2345

Fax:+886-3-579-7755

Email:info@aibt.com.tw